CNC Machining Services

Precision CNC Machining

Nexus Automation specializes in CNC prototype machining services. We work with some of the most recognized brands in medical devices, automotive, and consumer products to bring their most complex prototype projects to life. Our CNC manufacturing experience enables us to deliver accurate, high precision prototypes—right the first time.

With our fast quotes and personalized expert service, contact Nexus when your project demands a rapid response from a top-notch boutique CNC machining shop. We pride ourselves on offering both turning and milling in house. Our expert machinists each bring over 20 years of experience, allowing them to create parts that that deliver incredible precision to your specifications.

From our manufacturing facility in Livermore, CA, we can serve the entire United States with fast shipping for prototypes, parts, and components big or small.

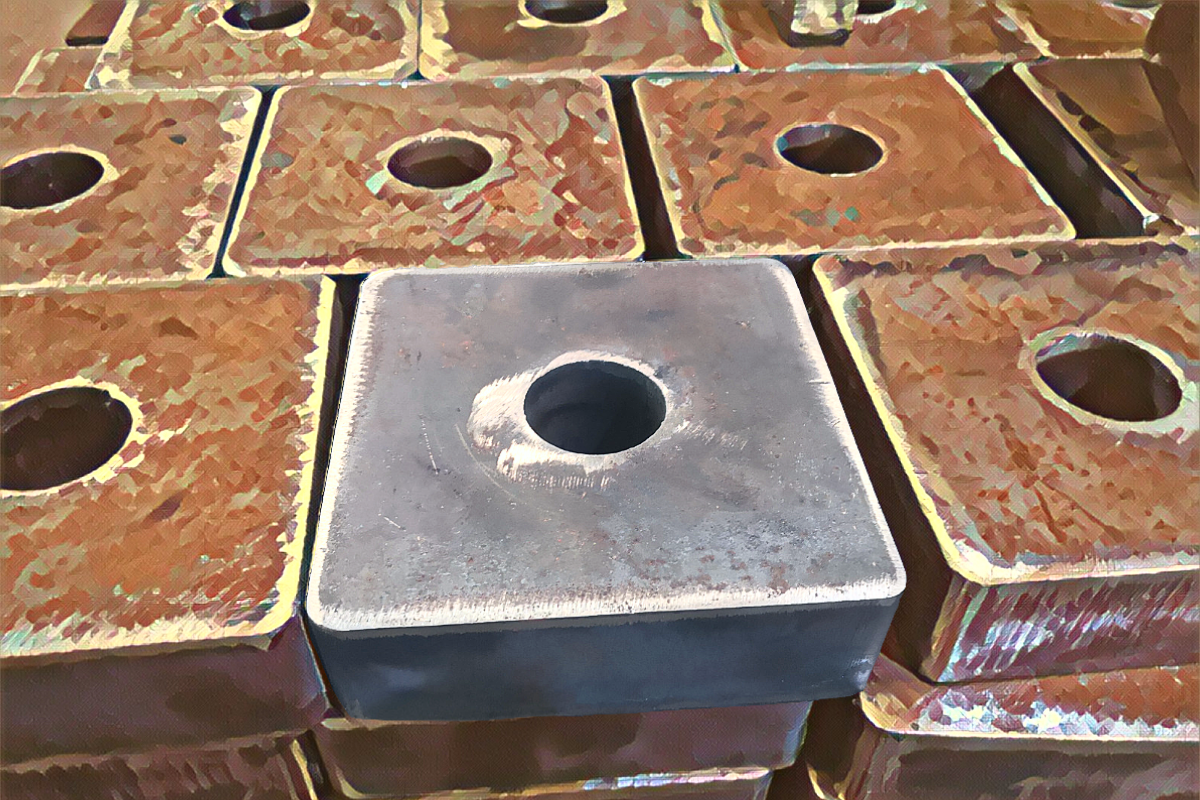

Custom CNC Projects Big & Small

-

CNC MILLING

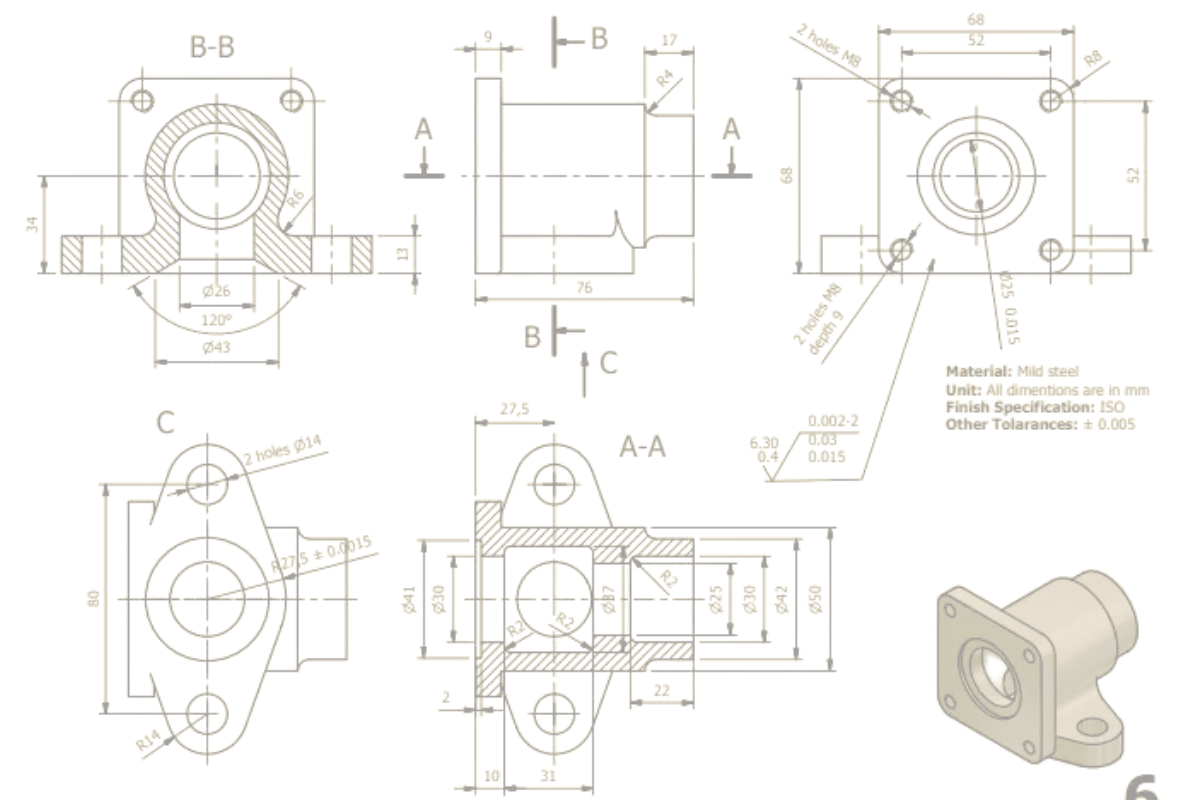

Our expert machinists are tool and die makers and skilled in CAM and CAD software. They can support the highest level of complexity and tight tolerances in the parts they manufacture.

-

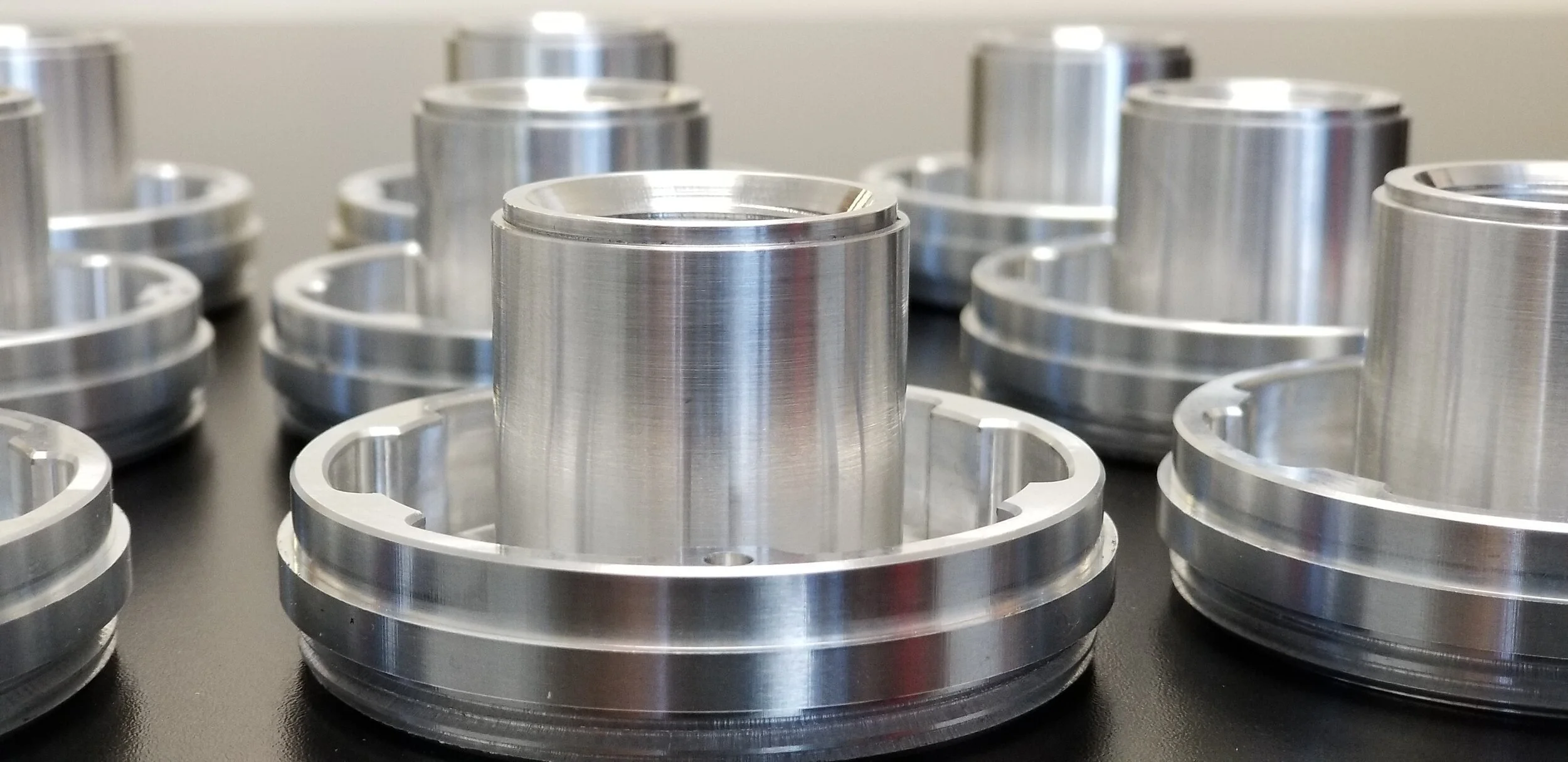

CNC TURNING

With CNC turning capabilities for both large and small projects onsite, Nexus is a one-stop shop for every type of part—round or square, and those with complex geometries.

Capabilities

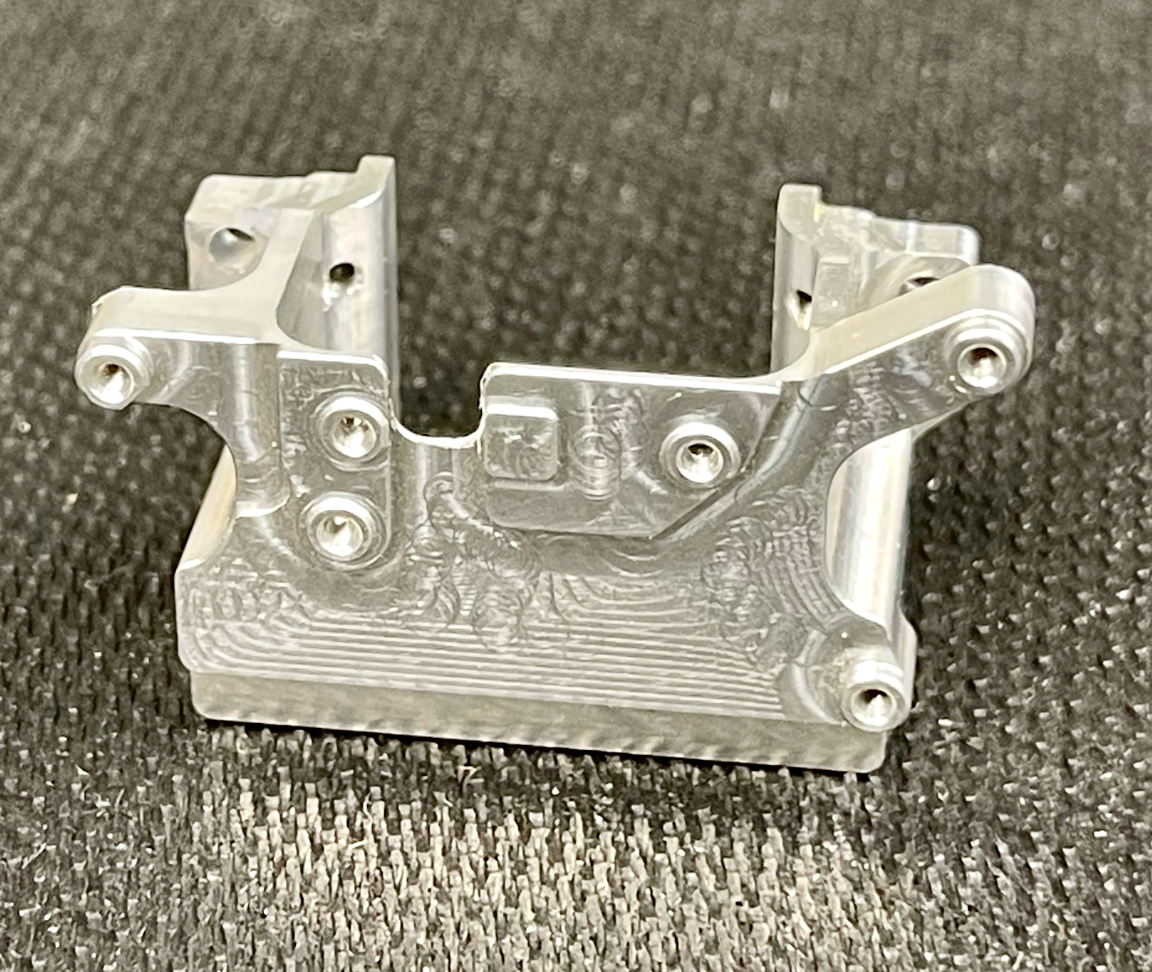

For Challenging CNC Machining Projects that Need Expert Capabilities

Our modern CNC machines and 30+ years of machining experience can handle small radius cuts and tight tolerances while maintaining the highest quality level, whether you need one prototype or one hundred.

Nexus produces some of the most complex, tight tolerance, uniquely designed machined and assembled components that average shops steer clear of. We welcome exotic alloy and tight tolerance projects and love to rise to take on challenges others won’t even quote on.

We live up to our ISO 9001:2015 and ISO 13485:2016 certifications with every project, and take pride in delivering accurate parts finished to the highest standard.

Machining Tolerances

While typical customer designs require tolerances of +/- .005”, it’s not uncommon for the Nexus team to see down to +/- .0002” for key characteristics and dimensions.

-

Our capabilities include holding milled positional tolerances to +/- .0002” and less for some specialty projects on both position tolerances and Datum related features.

-

On a wide range of materials, we routinely hold turned tolerances to +/- .0002”, and less for some specialty projects.

Reworked Prototypes

Manufacturing is complicated, and not every vendor can get your part or project right the first time. If you have pieces from another vendor that don’t meet your standards, we’re happy to put our expertise to the test and rework these pieces, so you can have a usable, high-performing part.

Sometimes you need to modify a part to add sensors, inspection ports, or other similar features for testing. We’re happy to work on these as well

“I’m thoroughly impressed by Nexus Automation’s efficiency and quality work.”

— Engineer at a Fortune 5 company

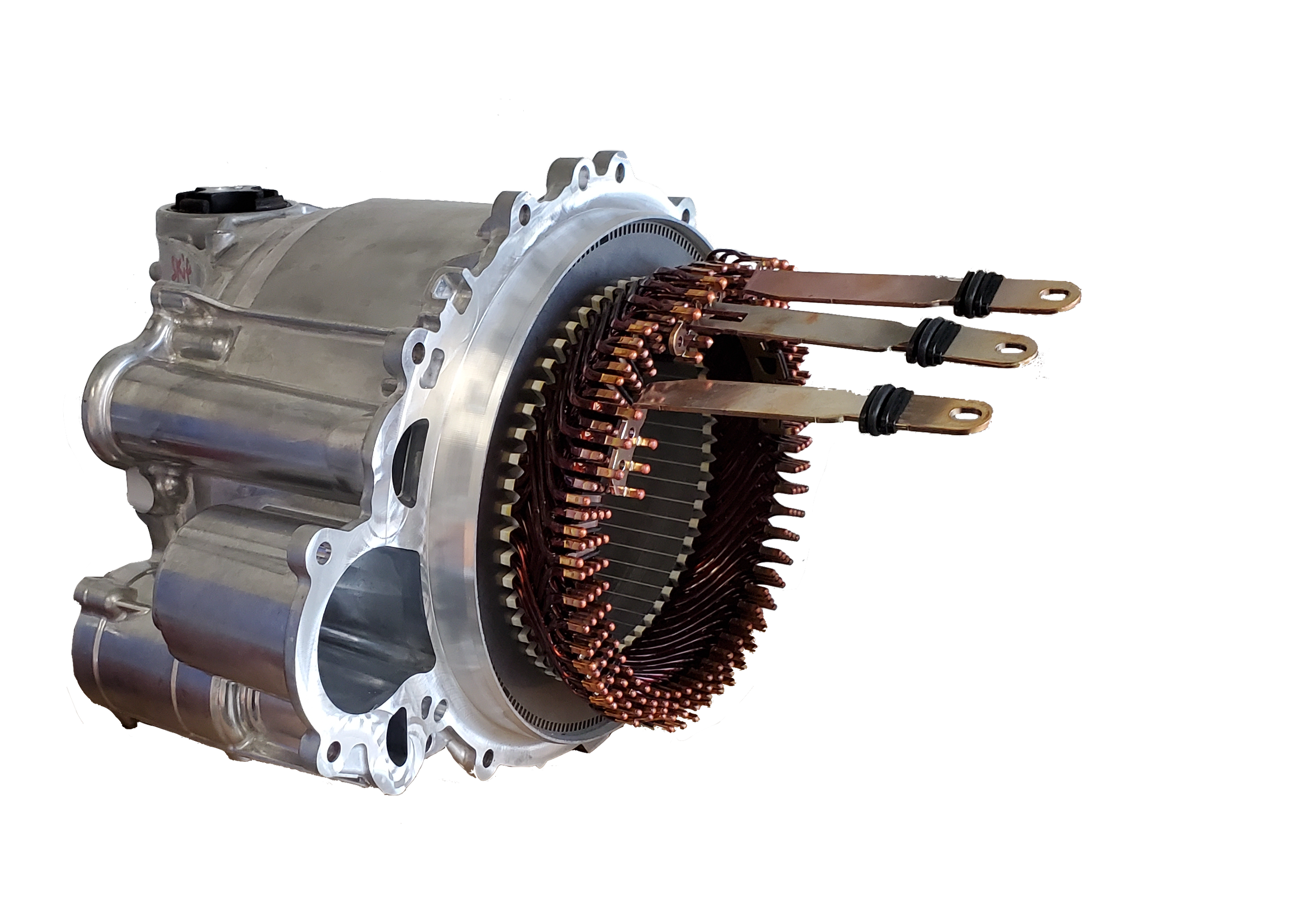

Contract Manufacturing

We consider this setup a win-win. It’s easy for us, easy for you, and delivered at a great value. Feel confident giving Nexus a partial assembly with your proprietary technology. Or have us create a part or assembly from scratch.

We machine all parts, build, assemble, and test electromechanical systems in our turnkey facility, making it easy to start with prototypes then, scaling to higher production.

Manufacturing Materials

The materials below are the most common we work with at Nexus, however, we manufacture with many exotics, so feel free to contact us with your special materials needs.

Stainless Steel

Steel

Tool Steel

Inconel

Titanium

Brass

Copper

Aluminum

PTFE (Teflon)

Nylon

ABS/Delrin

Acrylic

Polystyrene

HDPE

Nylon

PEEK

Polycarbonate

Polypropylene

Quality CNC Machining Services

-

ISO CERTIFIED

Nexus is ISO 9001:2015 and ISO 13485:2016 certified, so our customers can rest assured that their products and projects are produced with diligence and rigorously inspected before delivery.

-

QUICK TURNAROUND

Upload your design files and requirements and we’ll quote your parts within one business day. Nexus is committed and equipped to deliver your prototype and scaled production needs on-time.

-

ENGINEERING EXPERTISE

On average, each Nexus machinist has 20+ years of machining expertise. Paired with our trained MEs for design services and DFM feedback, we offer a seamless process and the highest-quality products.

Have a design ready to quote?

We love a good CNC machining challenge, manufacturing questions, or just helping out our ME and designer friends with their latest projects!