Wire EDM Services

Wire Electric Discharge Machining (EDM) Services

For Projects Combining Accurate Wire EDM Machining & Other Manufacturing Services

Unlike other shops that offer wire EDM machining services, Nexus Automation specializes in hybrid wire EDM / machining or turning for parts, prototypes, or one-off component projects. This approach minimizes cost while still allowing us to achieve super fine detail features that EDM is known for. Our customers rely on our high-quality EDM services for complex orders, design work from scratch, EDM feature add-ons to existing parts, and projects that require other machining processes. We typically work with standard alloys such as aluminum, stainless steels, nickel-based, titanium, copper tungsten and tungsten carbide, as well as exotics.

Nexus can produce parts that have intricate details or complex geometries. Our wire EDM machines can cut extremely accurate custom parts using a .002” wire, leaving radii as small as .0015” on internal corners and producing an EDM hole size of +/- .0002” or better for some projects.

Nexus’ wire EDM services are used in medical, automotive, aerospace, and electronics applications. For your projects requiring custom, high precision wire EDM, Nexus can deliver tight tolerances for the highest accuracy. We can also combine EDM services with other machining processes such as turning, milling, finishing, and assembly services, for a complete end-to-end solution.

WIRE EDM MACHINING CASE STUDY

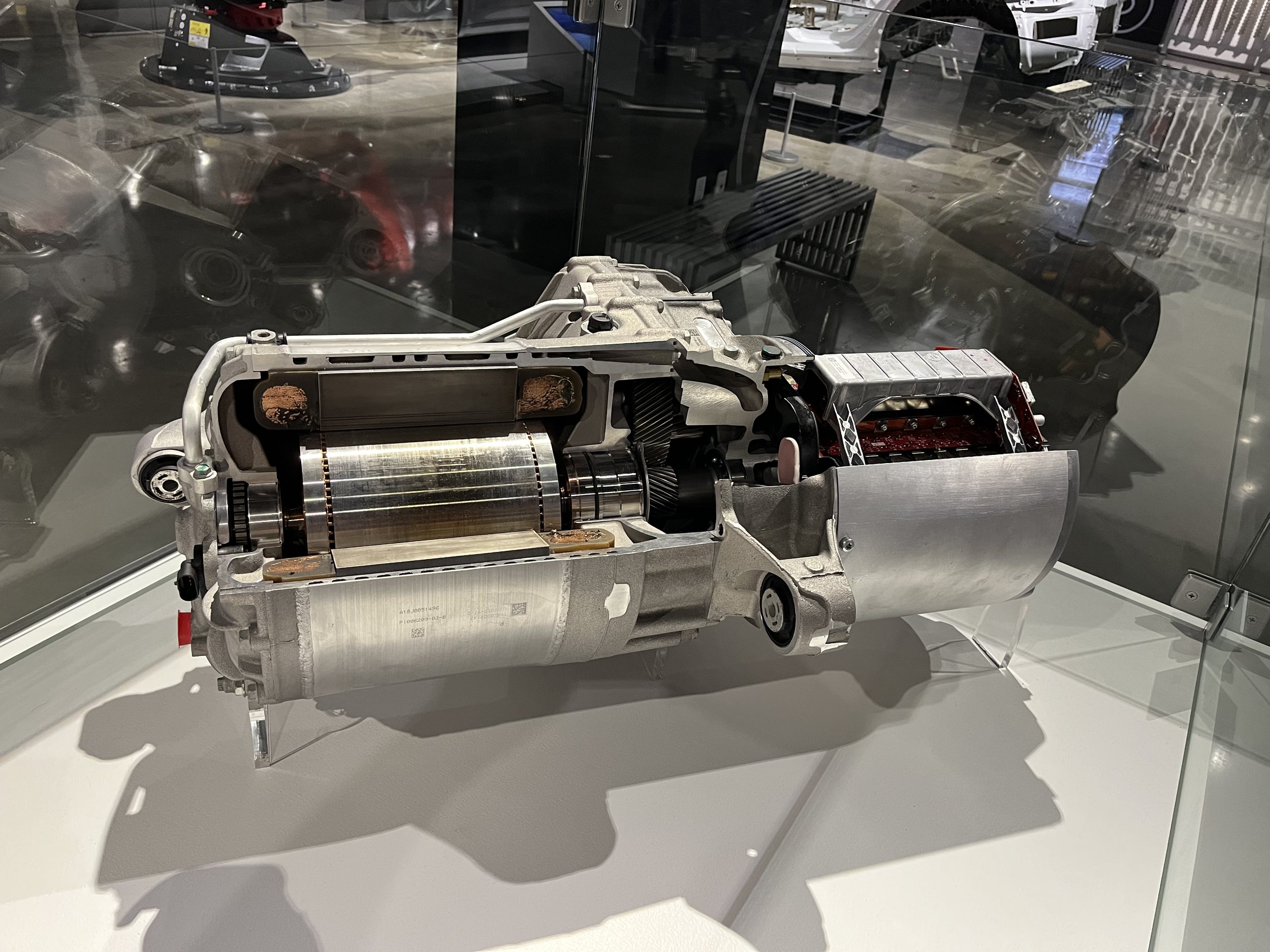

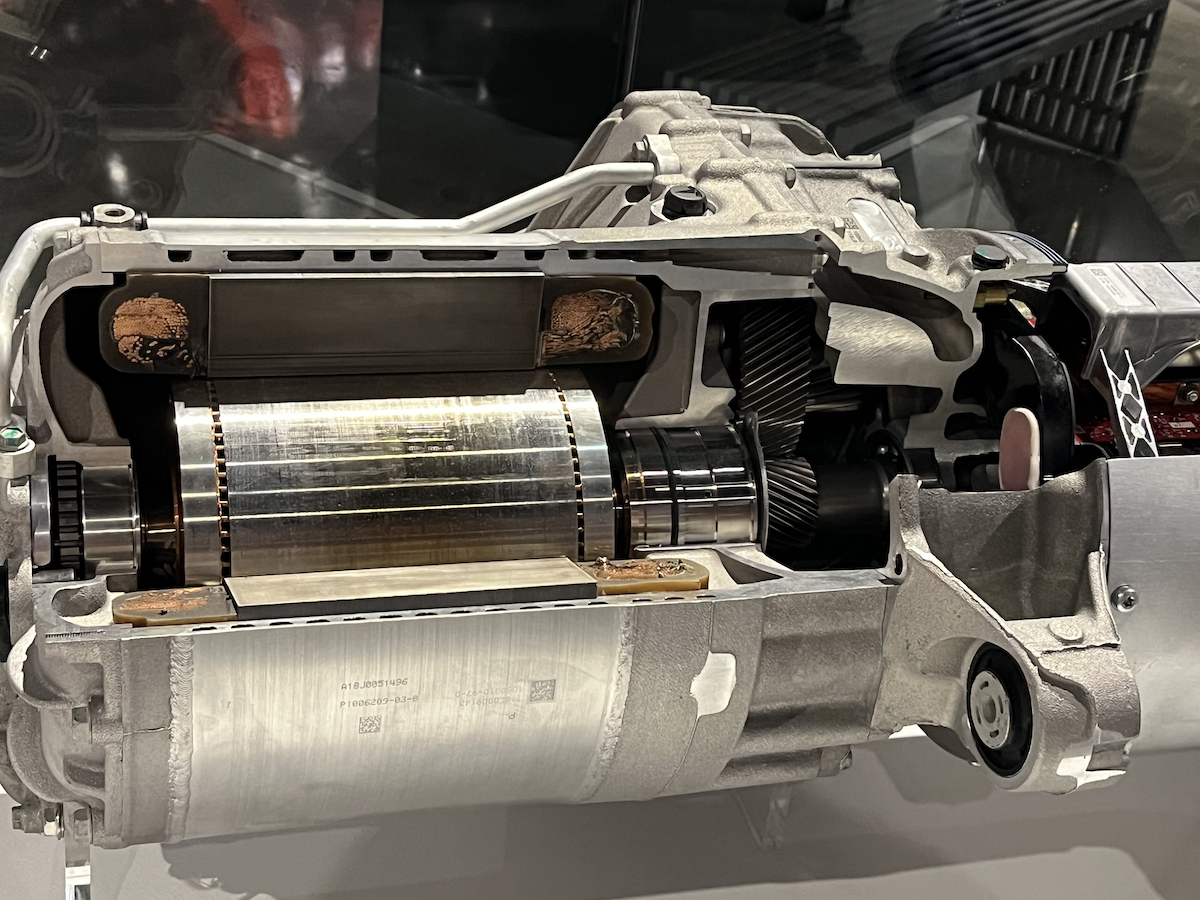

Tesla engages Nexus for challenging EDM project to expose drivetrain build for a Petersen Automotive Museum Exhibit

The Peterson Museum in Los Angeles is hosting the exhibition, “Inside Tesla: Supercharging the Electric Revolution”, November 2022 - October 2023. The collection includes an eclectic display of electric drivetrain models from multiple Tesla vehicle generations. We are proud to showcase our work as part of this exhibition display. By cutting through the drivetrain with our EDM, we were able to complete a seamless cut, even though there were more than 50 components.

Our technicians were able to create such a clean cut and finish, that looks like as if we were cutting through butter. No other tool nor team could have done the job! These assemblies have more than 10 different alloys, but that did not affect our work.

Why Nexus?

Our expert machinists are tool and die makers, skilled in CAM and CAD software, and can support the highest level of part complexity with tight tolerances.

With turning capabilities onsite, we’re a one-stop shop for every type of part—round or square, and those with complex geometries.

We use our wire EDM to achieve part precision and efficient manufacturability where low-impact machining and tight tolerances (+/- 0.0001) are essential.

Design ready to quote?

We love a good wire EDM challenge, manufacturing questions, or just helping out our ME and designer friends with their latest projects!