Assembly Services

Assembly Services for Unique and Low-Volume Electromechanical Builds

Our assembly and automation services are a natural compliment to the custom machining processes with offer at Nexus Automation. Whether project components are manufactured by Nexus, externally sourced, or provided by the customer, our in-house mechanical technicians follow our certified ISO 9001 and 13485 quality management procedures to assemble and test to exacting specifications.

This rare combination of high-precision manufacturing and assembly experience creates value in terms of accuracy and time and cost savings to streamline builds and reduce supply chain risk for customers.

The various machining and manufacturing methods we work with at Nexus allows us great flexibility to build assemblies that involve complex fit, form, and function that other shops find too challenging. Our experienced engineers and assembly technicians are available to provide advice or manufacturing recommendations for your project to achieve structural benefits, cost savings, and assembly efficiencies.

To deliver the most value-add for our customers, we can offer a comprehensive process that can incorporate component manufacturing, part sourcing, existing part modifications, for an end-to-end mechanical assemblies service. We have partnered with customers to assist with inventory management and reducing overhead for assembled products.

Nexus is a premier assemblies services provider to some of the most recognized global medical, automotive, and consumer products brands.

We Love a Good Assemblies Challenge

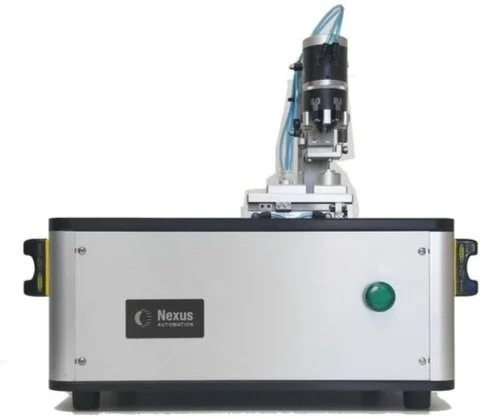

All equipment and resources for successful electrical wiring and mechanical assembly are onsite within our facility. We design and build assembly systems and automation solutions from bench-top stations to fully automated work cells — concept to creation.

To get your product right, our team is well-versed in utilizing many mechanisms, including pick and place, laminating, heat sealing, ultrasonic welding, inspection, and more.

Our Assembly Capabilities

-

STANDARD SERVICE

Our standard assembly service supports projects with parts such as tabs, brackets, harnesses, connectors, RF components, hinges, bearings, pins, and other electrical and mechanical components.

Our turnkey capabilities, deadline-driven support, and experienced design engineers ensure assemblies are build in the most efficiently.

-

MIXED BUILD SERVICE

We can integrate parts we produce with off-the-shelf parts, customer provided parts, as well as collaborate with partners for other custom components. Nexus can provide modification services for any stock parts.

Our team is well-versed in many mechanisms, including pick and place, laminating, heat sealing, ultrasonic welding, inspection, and more.

-

UNIQUE PROJECTS

For unique projects, we happily accept those with one-off specifications. We can produce complete assemblies of ongoing releases in shipments of 50 units or more.

Our assemblers can build complex assemblies that include wiring, soldering, building wire harnesses, or integrating electronics.

“I would recommend the Nexus team to anyone looking to design and automate their machine.”

— Automation Engineer at a biotech company

Selection of Assembly & Automation Projects

-

MATERIALS HANDLING

The material handling systems we design eliminate cumbersome steps and unnecessary parts. We have the expertise to design and build automated material handling equipment that precisely manipulates, aligns and places parts in the right orientation.

Our material handling systems have utilized mechanisms such as pick and place, adhesion, sealing, dispensing, and lamination.

-

AUTOMATED ASSEMBLY SYSTEM

Our biotech client’s goal was to create a cartridge system that would achieve faster, more accurate assembly and higher production for diagnostic testing.

We designed and built a fully automated assembly system with 12 axes of motion and integrated two vision systems. The processes included placing multiple magnets, peeling, and placing labels from a roll using a reel-to-reel mechanism, flipping the part, and thermal bonding a graphite gasket.

-

LIQUID HANDLER ASSEMBLY

After more than a year and a half and $1.25M in development with another large diagnostics company, our biotech client developed an inefficient automated liquid handler for isolating circulating tumor cells from blood samples, one chip at a time. They needed a new solution.

In eight short weeks, we designed and built a custom liquid handler which processed four chips at once. This automation accelerated our client’s growth, resulting in the creation of more than 100 replicas of the same system — and assisted in the company’s acquisition by a major investor.

-

AUTOMATED ASSEMBLY SYSTEM

Our biotech client’s goal was to create a cartridge system that would achieve faster, more accurate assembly and higher production for diagnostic testing.

We designed and built a fully automated assembly system with 12 axes of motion and integrated two vision systems. The processes included placing multiple magnets, peeling, and placing labels from a roll using a reel-to-reel mechanism, flipping the part, and thermal bonding a graphite gasket.

-

CLEANING SYSTEM FOR MICRO-ARRAYS

Our bioscience client needed to automate their challenging manual process of removing debris from micro-arrays (DNA chips).

We designed a comprehensive prototype system with the flexibility to choose from multiple cleaning processes. These processes included the ability to select any chip among an array of eight, add/remove weight to determine the exact pressure it would take to remove debris without damage, dispense cleaning solvent in two different ways, and allow for a custom cleaning pattern. The system was also designed and approved for CE certification.

-

ARRAY PUNCH ASSEMBLY

Our biotech client’s process for removing sharp-edged steel arrays was unsafe/dangerous. To extract a single array, all five neighboring arrays needed to be manually removed and stored in order, causing potential tracking errors.

We designed a semi-automated bench top punch system that eliminated all safety concerns allowing the client to remove any or all 12 arrays with ease. After removal, the arrays were organized in custom-designed, positively stacking trays for long-term storage.

-

GLUE MACHINE AUTOMATION PROJECT

Our pharmaceutical client wanted to automate their dull and dirty manual process of dispensing glue on the outer perimeter of a tube (5mm diameter, 3mm high).

We built an automated glue machine designed with an end effector. The new glue machine picked up each tube from its interior surface and dispensed small uniform amounts of viscous glue on the outer perimeter.

-

O-RING MACHINE AUTOMATION PROJECT

Our pharmaceutical client needed an automation solutions for the dull/repetitive manual task of hand placing an O-ring onto a vial cap .

We designed and built a fixture, with a two-handed safety operation, to automatically and precisely attach O-rings. The result was increased throughput, precise and secure placement of O-rings, increased productivity, and reduction in employee injuries.

-

DRUG DELIVERY DEVICE

Our specialty pharmaceutical/therapeutics client needed a drug delivery device to automate their manual process.

We created a system featuring a reel-to-reel mechanism and formed a blister in a thermo-former. The blister was punched precisely using vision technology. A 4-axis SCARA robot then affixed a plastic part before an impulse heater sealed it. The drug delivery device was tested for leaks before being placed in a storage/transport tray.

Have a design ready to quote?

We love being the MacGyver to solve our customer’s assembly and automation design or build dilemmas.